The start of TSMC Arizona chip production – which will include chips for older Apple devices – has now been officially delayed by the company. Production was scheduled to begin in late 2024, and this has now been pushed back to early 2025.

Apple’s chipmaker had previously acknowledged that construction work had fallen well behind schedule, but had said at the time that this “[did] not necessarily mean” that initial chip production would be delayed …

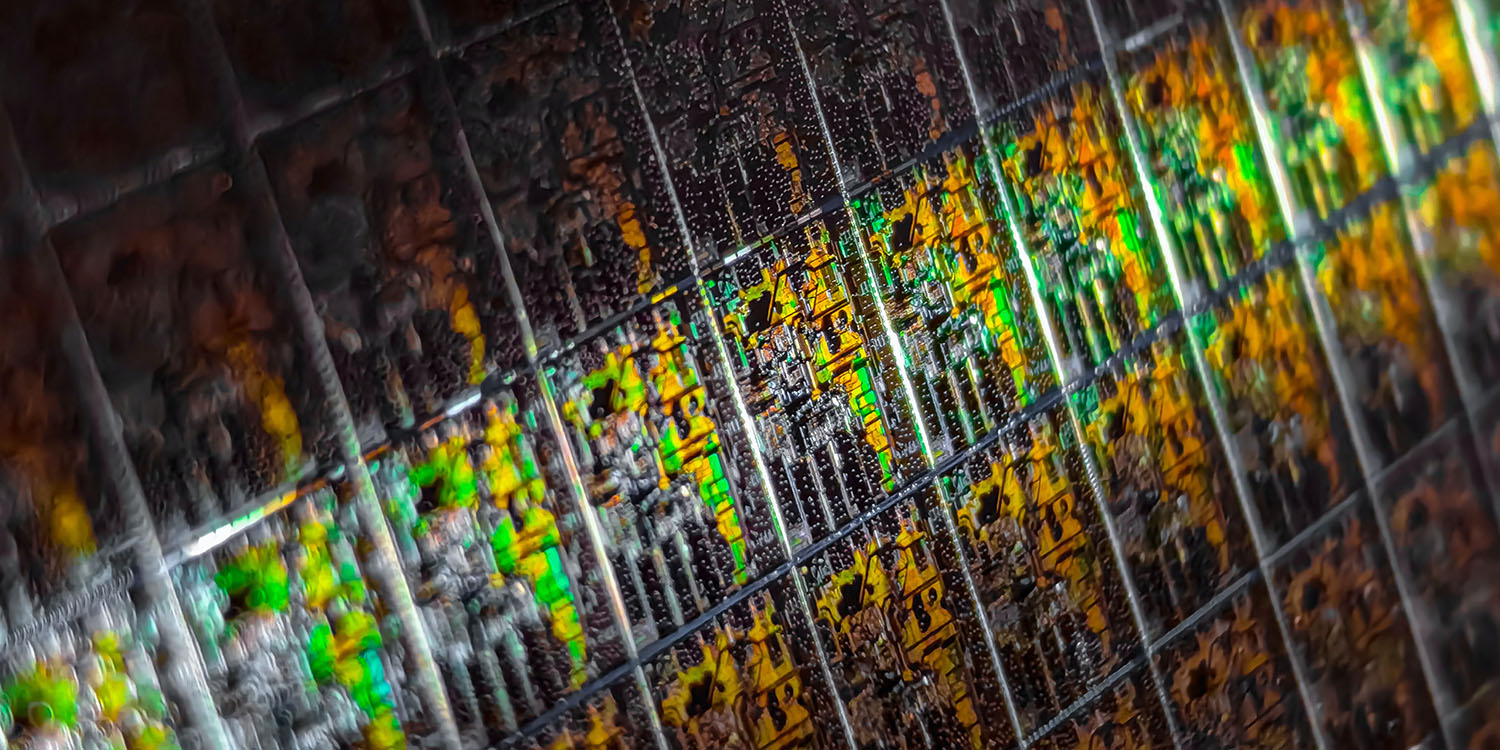

Background on the plant

TSMC first announced its plans to build one or more chip plants in Arizona back in 2020. It was claimed that 1,600 US jobs would be created, including those in a local supply chain.

The company sought substantial subsidies from the US government in order to proceed. Apple supported this bid, lobbying on TSMC’s behalf through the CHIPS Act, a $50B program to promote chip fabrication within the US.

Apple has said that the plant would make chips for Apple’s devices, though only for older ones.

TSMC Arizona chip production delayed

Late last month, the Taiwanese company acknowledged that construction work was significantly behind schedule. The plan was for chip fabrication equipment to come online for initial test production around September of this year, and it’s instead expected that this won’t happen until next February or March.

At the time, TSMC claimed that this didn’t necessarily mean that the start of customer chip production would be delayed, as there was always contingency time in the plan. However, Nikkei reports that company chairman Mark Liu has now acknowledged that the delay will indeed affect production plans.

Taiwan Semiconductor Manufacturing Co. said it will push back the start of mass production at its plant in Arizona to 2025 due to a shortage of skilled workers and technicians needed to move equipment into the facility.

TSMC Chairman Mark Liu said the world’s biggest contract chipmaker is entering a critical phase of handling and installing some of the “most advanced equipment” at the plant.

Controversies remain

The history of such deals – where American taxpayers agree to pay large subsidies to foreign companies to set up production within the US – isn’t great. A similar deal with Foxconn for US production in Wisconsin came to nothing, after the state had spent almost a billion dollars in infrastructure for the non-existent factories.

In this case, at least construction is well underway, but only at the cost of TSMC demanding twice as much cash as initially offered, and bringing in hundreds of workers from Taiwan. There have also been reports of serious safety issues at the plant, which have been only partly denied by TSMC.

FTC: We use income earning auto affiliate links. More.

Comments