China

China has been fundamental to Apple’s historical success, but is also arguably the greatest risk to the company’s future.

Table of contents

Why are most Apple products made in China?

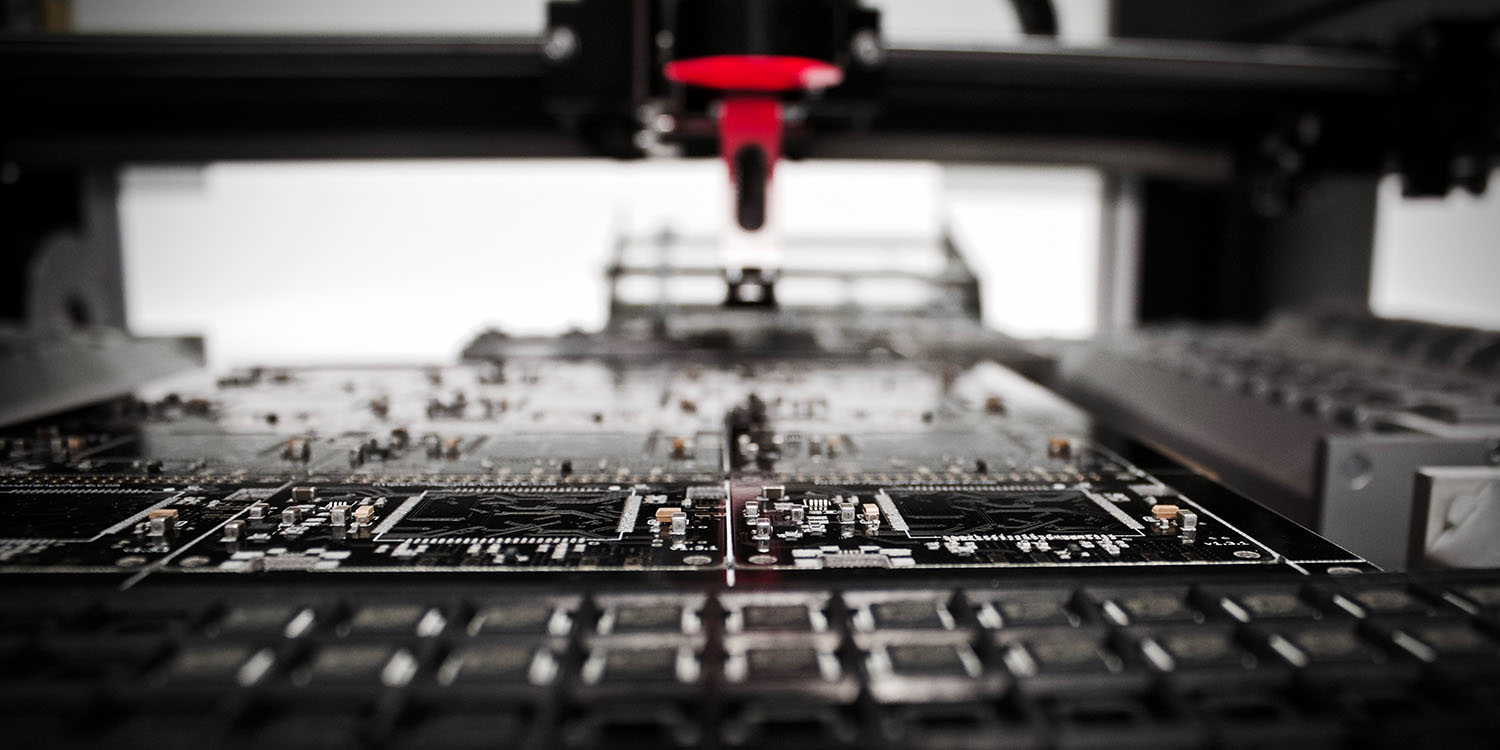

Although everyone assumes Apple products are made in China because labor is cheap there, that’s only part of the story – and an increasingly small part, as the company’s assembly partners move toward more and more automated operations.

Steve Jobs originally transferred most Apple manufacturing to China because it was the only country in the world with a huge ready-made supply-chain network, and the ability to scale up production almost overnight. There are three main reasons China – and specifically the Shenzhen area – is such a powerful manufacturing center.

First, the city is strategically placed, serving as the gateway between mainland China and Hong Kong. It is one of the largest shipping centers in the world, with a massive container port.

Second, the Chinese government established Shenzhen as the first Special Economic Zone (SEZ) in the country. SEZs are designed to encourage enterprise through relaxed planning regulations and generous tax incentives – and crucially, to facilitate foreign investment in local companies. It is this, as much as its geographical advantages, which has enabled it to grow at such a pace.

Third, that SEZ was established way back in 1980, meaning that the city has had over 40 years to grow into the manufacturing center of the tech world. Apple relies on a huge network of suppliers and sub-contractors, some of which may make just a single tiny component. The majority of them are based in Shenzhen and its immediate surrounds, so the logistics of bringing everything together in one place for assembly are straightforward.

What are the risk factors with China?

Being over-dependent on China carries a number of risks.

First, there is the generic one: Being overly dependent on any one country is a strategic risk. For example, the COVID-19 pandemic originated there, and had a massive impact on manufacturing capacity. Anything from a natural disaster to political upheaval could disrupt operations within a single country, so it is always wise to have a diverse range of manufacturing centers around the world.

Second, the relationship between the US and China has often been fraught. The trade war started by the previous US administration was a particularly low point, but continued tensions mean that there is always a risk of disruptions to trade between the two countries.

Third, it is increasingly damaging to Apple’s reputation to be so closely associated with a country that has a worsening human rights record – especially when the iPhone maker has no choice but to comply with local laws, however much they may conflict with the company’s own values. Apple has been required to remove VPN and a variety of other apps from the Chinese App Store, allow the iCloud data of Chinese customers to be stored on government-controlled servers, and more. Additionally, there have been growing reports of forced labor in China, including within many different areas of Apple’s supply chain.

What is Apple doing about it?

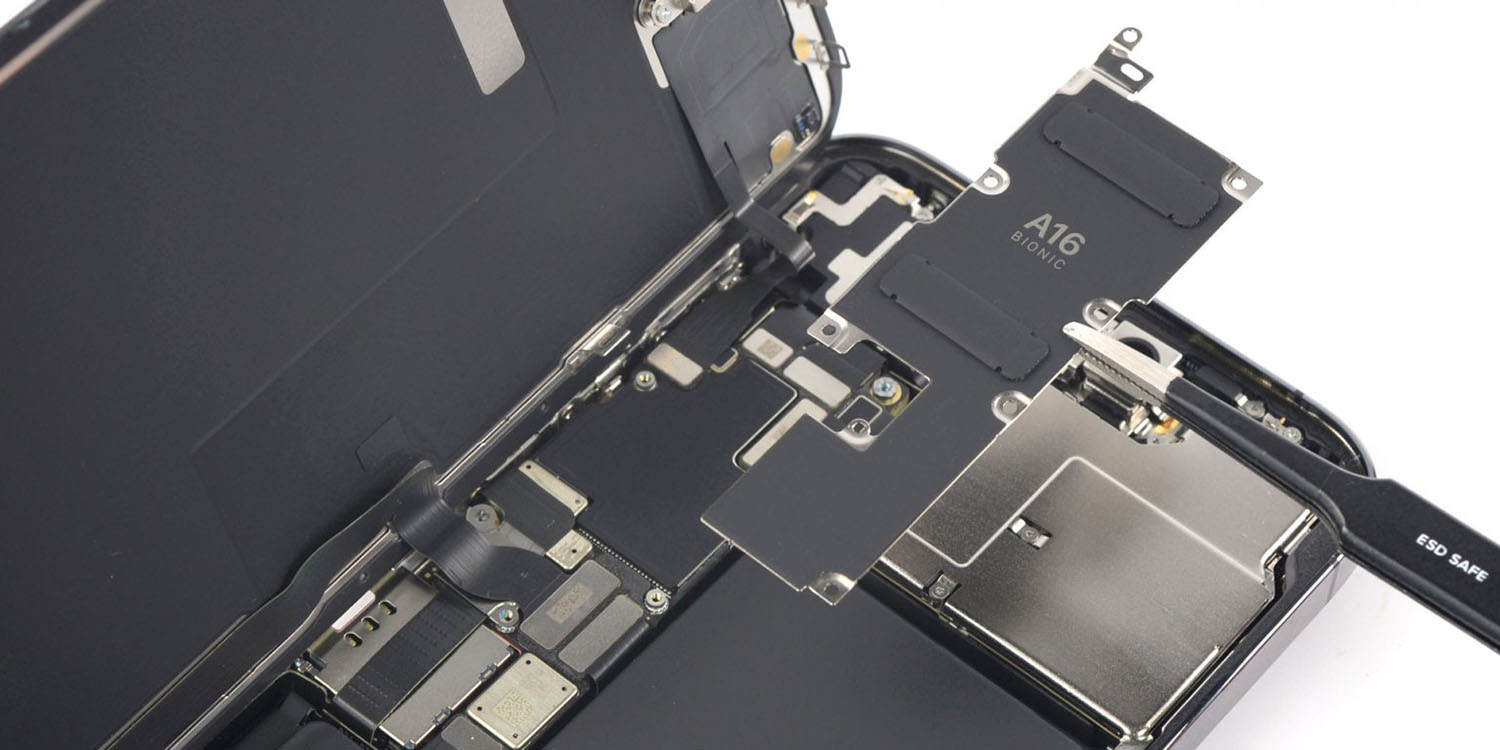

Apple has been working for a long time on diversifying its manufacturing operations, and has in recent years accelerated the pace at which it is doing so.

As explained above, this is far from an easy undertaking, but Apple now has major manufacturing operations in India, Thailand, Malaysia, and the Philippines, among other countries.

In India in particular, we are seeing the very early stages of a complete supply-chain infrastructure as the government uses a mix of carrot and stick to encourage companies to manufacture more of their components within the country – namely, tariffs on imports of components and tax breaks for local production. COVID-19 lockdowns in China also saw Apple move some iPad production to Vietnam for the first time, but it’s clear that the risks of over-dependence on China have never been greater.